Solid State Analysis

Home » Services » Analytical Chemistry » Solid State Analysis

Cormica provides industry-leading solid state characterisation services to accelerate your pharmaceutical and combination product development. With GMP, GLP, and ISO 17025 accredited labs across the UK, EU, and US, our expert scientists deliver fast, reliable insights to support formulation, regulatory submission, and product quality.

Solid state characterisation is key to a detailed understanding of the physical properties of pharmaceutical solids and plays an important role in the successful development of many pharmaceutical dosage forms, along with many other products. The physical properties of a material can have significant impact on performance, processability, stability and appearance, and the quality, efficacy and bioavailability of the finished product.

Our comprehensive suite of analysis instrumentation, combined with the expertise and experience of our analytical team, enables you to better understand the properties of your material in the solid state, and optimise your solid form.

Why Partner with Cormica?

- GMP, GLP, and ISO 17025 Accredited

- Trusted by Top 20 Global Pharma Companies

- Global Lab Network in UK, EU, and US

- Full suite of Testing Services: R&D to Post-market Surveillance

- Proven Expertise in Combination Products

Characterisation Capabilities

We offer comprehensive solid state characterisation packages including:

- Thermal analysis (DSC, TGA)

- Specific surface area and porosity

- Moisture and solvent content

- Dynamic vapour sorption and microscopy

- Particle shape and size distribution,

- Physical stability and X-Ray Powder Diffraction for crystallinity

- Polymorphic form

Our experienced team works with you to better understand your powder.

Thermal / Moisture Analysis

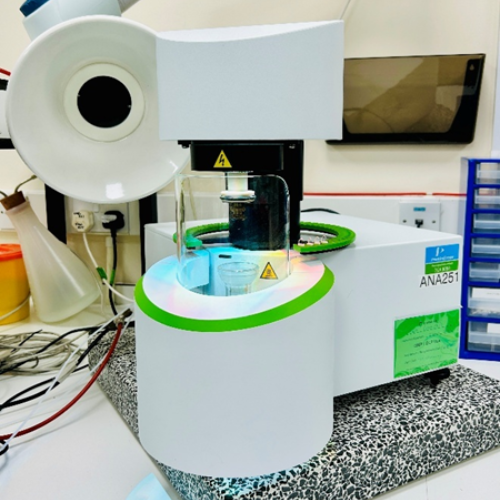

- PE Differential Scanning Calorimeter, DSC 4000

- PE Thermogravimetric Analysis, TGA 8000

- Metrohm Karl Fischer Titration

- Loss on Drying

- SMS Discovery Aqua Dynamic Vapour Sorption

BET SSA and Porosity

- Micromeritics TriStar II 3020

- Micromeritics TriStar 3000

Microscopy

- Morphologi4-ID Particle Size & Shape by Optical Imaging

- Scanning Electron Microscopy

- SEM-EDX Elemental Analysis

- Carl Zeiss AXIO IMAGER Optical Microscope

Also Available

- X-Ray Powder Diffraction

- Particle Size Distribution by Laser Diffraction

- Particle Size Distribution by Light Scattering

- Physical and Chemical Storage Stability

- Rheology

- Residual Solvents Analysis by GC-FID

Instruments & Applications

Understanding and measuring thermal properties of materials is crucial in many fields, including pharmaceutical actives and excipients, polymers, plastics, composites, organic materials, chemicals, biological samples, and others.

Differential Scanning Calorimetry (DSC) and Thermogravimetric Analysis (TGA) are used to understand critical materials properties such as decomposition temperatures, volatiles content, hydration or solvation state, thermal phase changes, glass transition temperatures, melting temperatures, crystallization temperatures, and other endothermic or exothermic effects.

These properties play an important role in understanding the behaviour of materials during processing, on storage, and during heating or cooling processes and allow you to make informed decisions regarding material formulation and manufacturing processes.

At Cormica our Perkin Elmer DSC and TGA instruments can be used in conjunction to provide this key information. Additional applications include polymorph identification / quantification, API-excipient compatibility studies, QC batch release and physical stability.

The moisture / solvent (volatiles) content of a material affects the processibility, stability / shelf-life, usability and quality of a product. Accurate volatiles content determination therefore plays a key role in ensuring quality and efficacy for many industry sectors, including pharmaceuticals and chemicals.

Typically, moisture content is determined via a thermogravimetric approach in which the sample is heated and the weight loss due to evaporation of moisture is recorded; this can be carried out at Cormica using our Thermogravimetric Analyser (TGA) or via a traditional vacuum oven approach. Additional data interpretation of TGA data can provide insight into the nature of the volatile content, for instance bound or unbound water, water of hydration, nature of organic solvent, depending on the mass loss associated and the volatilisation temperature or temperature range of the mass loss.

Additionally, quantitative determination of water content over a wide range can be determined using our Metrohm combined volumetric and coulometric Karl Fischer instruments. The accompanying Karl Fischer oven allows for quantitation of water content via headspace sampling.

In contrast to moisture content analysis, Dynamic Vapour Sorption is used to measure how samples interact with moisture vapour, by means of gravimetric assessment at a range of relative humidities. At Cormica a typical DVS analysis might comprise, for example, mass change monitored as a function of time over the humidity range 0-90 % RH, with the humidity increased and decreased in a stepwise manner (isothermal conditions).

Understanding the nature of such interactions is important for predicting stability, investigating hydration / dehydration, and determining hygroscopicity, plus probing amorphous content, and other properties such as polymorphism and porosity.

A detailed knowledge of the impact of exposure to moisture is vital in terms of formulation development; the results obtained from DVS analysis inform production processes, packaging configurations, shelf-life and more.

Many physical characteristics can influence the surface area of a sample, including particle size, pore size, pore volume and surface roughness. In turn, the surface area and porosity of a material will influence everything from flowability and processability, to dissolution performance, product delivery, and ultimately, bioavailability.

At Cormica, we understand the critical role that surface area and porosity play in the performance and quality of pharmaceutical and medical products and those from other industries. Our surface area and porosimetry analyses provide comprehensive insights into the physical characteristics of a wide range of materials, helping to identify process manufacturing issues, assess differences between supplied vendor batches, facilitating research and development troubleshooting, and also as a key quality control / batch release test, complementing particle size analysis.

At Cormica we offer a wide range of microscopy techniques, to enable the visualisation of your sample. Particle imaging allows for an understanding of particle size, morphology, association and condition / characteristics, providing crucial information for powder characterisation from early development through to QC quality control, and is crucial for the contextualisation of laser diffraction particle size data, for instance.

Optical and electron microscopy are often the starting points for successful materials related problem-solving and the identification of unknown particulates, and provides a wealth of information to support research into diverse range of sample types.

Particle Shape

- Acicular / Needle-like

- Columnar / Prismatic

- Equant / Cubic

- Flake

- Lath / Blade

- Plate

Particle Association

- Agglomerate

- Aggregate

- Conglomerate

- Drusy

- Lamellar

- Sperulite

Particle Condition / Characteristics

- Occlusions / Inclusions

- Angular / Rounded

- Colour / Opacity

- Cracked / Split

- Pitted / Porous

Our service offering encompasses everything from bespoke characterisation packages to one-off, niche testing, and includes method development, pre-validation, validation, method transfer and QC testing, plus storage stability.

Packages can include: particle shape and size distribution, specific surface area and porosity, moisture, solvent or volatiles content, dissolution and solubility, solution stability, moisture stability (DVS), thermal properties (DSC, TGA), crystallinity / amorphicity and polymorphism (XRPD), morphology and association (optical and electron microscopy).

Orthogonal and Supporting Techniques

- Solid state characterisation by X-Ray Powder Diffraction

- Particle Size and Shape Analysis

- APPS 2000 Light Obscuration particle size analysis for foreign particulate matter and sub-visible particles, USP <788> and USP <789>

- Rheology (Kinexus Ultra+)

- Residual Solvents Analysis by GC-FID (USP <467> and in-house methods)