Chemical Characterisation in Medical Devices: Why We’ve Expanded Our E&L Capability with PAL3 Series II Technology

A Broader View of Chemical Characterisation

Chemical characterisation in medical devices is often reduced to a discussion about extractables and leachables (E&L). In practice, the expectations from regulators, toxicologists and manufacturers go much further. A complete characterisation strategy now needs to consider extractables, leachables, residual process chemicals, sterilisation by-products, breathing pathway emissions and the analytical platforms capable of detecting compounds across different matrices and polarities.

At Cormica, this broader view is the foundation of how we approach chemical characterisation, and it’s the reason we have recently expanded our capabilities.

Continue reading below:

Author:

Luminita Moraru

Luminita Moraru is the Analytical Chemistry Manager at Cormica. Lumi is highly experienced in designing studies to comply with ISO 10993 standards for contact medical devices and ISO 18562 on gas pathway medical devices as part of the Biocompatibility process.

Share with your colleagues:

Regulatory Standards Guiding Our Work

Our studies are built around the current state of the art, including:

- ISO 10993-12 and ISO 10993-18 for extraction design, identification and quantification

- ISO 18562 Parts 1–4 for breathing pathway devices, including VOSs, condensate and particulates

- USP <1663> and <1664> for E&L methodology and toxicological assessment

- FDA Draft Guidance (September 2024) for chemical analysis in biocompatibility submissions

These provide the framework we use to plan, execute and interpret analytical and toxicological studies.

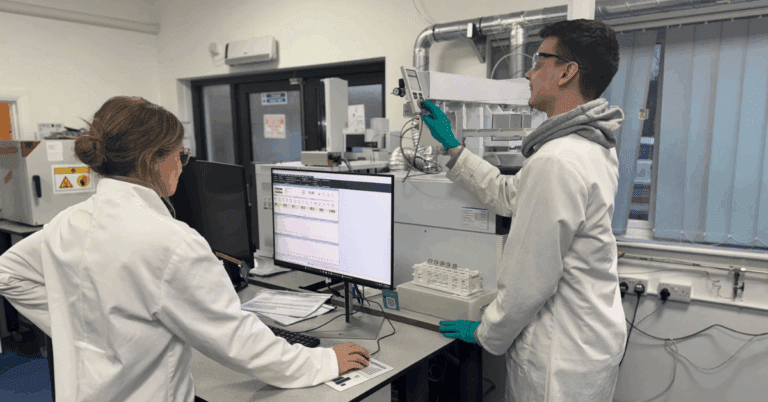

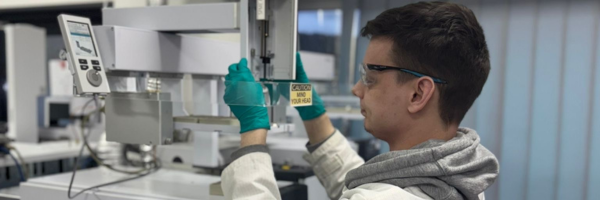

Expanding Our GC-MS Capability with PAL3 Series II Autosampler

To strengthen our analytical offering, Cormica has acquired the PAL3 Series II Autosampler, which enhances our ability to separate and analyse a broader range of compounds that may be released as extractables and leachables from medical devices.

The system incorporates multiple sampling and injection modes:

Enhanced Injection and Sampling Techniques

The system incorporates multiple modes that improve analytical reach and flexibility:

Headspace SPME

Samples are heated in sealed vials, releasing volatile organic compounds. These are adsorbed onto the SPME fibre, desorbed in the GC inlet and detected by mass spectrometry.

Direct Liquid Injection

Supports conventional GC-MS workflows for compatible extracts from materials or components.

SPME Arrow

An enhanced SPME format offering increased extraction efficiency and selectivity through fibre-coated arrows with different chemistries (e.g., polar or non-polar coatings), selected based on expected analytes.

Why SPME Matters for E&L Testing

By incorporating these SPME formats, our team can now analyse compounds extracted into matrices that are not compatible with direct GC–MS injection, such as aqueous or highly polar solvents. This is essential for detecting polar and semi-polar compounds released under exaggerated conditions or clinically relevant use scenarios.

Extractables are compounds released under exaggerated conditions designed to simulate product ageing, storage or sterilisation. Leachables are substances that migrate under clinically relevant conditions and may be available to patients during use.

Because both extractables and leachables can be polar, mid-polar or non-polar, selecting the right analytical techniques is critical to identify and quantify compounds at levels relevant to toxicological risk assessments.

The integration of SPME within our workflows offers practical and scientific advantages. It reduces solvent incompatibility issues, liquid–liquid extraction steps, sample transfer and associated recovery loss, risk of missing analytes in polar or semi-polar matrices

This allows us to provide cleaner chromatographic data and improved confidence in compound recovery, particularly at low levels.

From Detection to Toxicological Relevance

Once compounds extracted, separated, detected and identified or tentatively characterised, we apply the AET (analytical evaluation threshold) is applied is evaluated further and, where possible, identified through mass spectrometry, fragmentation data and library interpretation.

A robust toxicological risk assessment depends on the breadth and quality of the analytical data, and our expanded capability enables us to generate data that supports confident decision-making.

Preparing for the Future of Device Safety

The way forward in the industry involves chemical characterisation must reflect the full lifecycle and clinical context of a device. That means accounting for:

- Exaggerated and simulated-use conditions

- Material and process residuals

- Sterilisation impacts

- Gas pathway emissions

- Toxicological interpretation of detected compounds

Our investment in the PAL3 Series II Autosampler and advanced SPME workflows ensures we can meet these expectations and provide high-resolution analytical support for medical device manufacturers.

Plan Your Next Study With Confidence

If you are updating your chemical characterisation strategy or planning an E&L or ISO 18562 study, our team is ready to help accelerate your submission and ensure patient safety.

Our experts can help you generate reliable analytical evidence that supports patient safety and accelerates approval timelines. Cormica provides a complete suite of chemical characterisation services across the UK, US and EU, supported by GMP, GLP and ISO 17025 accredited laboratories and a team that understands what regulators expect to see.