Biological Evaluation Plan (BEP)

Home » Services » Consultancy » Biological Evaluation Plan

A Biological Evaluation Plan defines the strategy to demonstrate that your medical device is biologically safe for its intended use, in line with ISO 10993-1 and relevant regulatory frameworks (EU MDR, UK MDR, FDA).

It is overwhelming and time-consuming for manufacturers to navigate complex biocompatibility requirements, keep pace with evolving ISO 10993 expectations, or avoid redundant testing.

Unnecessary animal studies and incomplete justifications often consume valuable time and financial resources that could be directed toward innovation and growth.

Our cutting-edge experts transform this complexity into a clear, compliant, and efficient biological evaluation strategy ensuring your resources are used where they bring the greatest value to your business.

We translate regulatory requirements into a clear, evidence-based plan by minimizing testing costs, avoiding delays, and ensuring thorough risk evaluation and full compliance from the start.

Our BEP services

- BEP Authoring & Review — fully aligned with ISO 10993-1:2025, MDR Annex II & III, and FDA guidance.

- Gap Analysis — assessment of existing data to identify redundant or additional endpoints, and well as providing new justification to align with new requirements of medical industry

- Toxicological Risk Assessments (TRA) — in accordance with ISO 10993-17, MDR and FDA draft guidance.

- Material & Chemical Characterization Review — interpretation of ISO 10993-18 data and extractables / leachables.

- E&L Strategy Development — for polymers, coatings, and packaging materials.

- Integration with Risk Management — seamless alignment with ISO 14971 and clinical evaluation documentation.

The Biological Evaluation Plan Process

- Information Gathering – Review of materials, manufacturing, and sterilization details.

- Gap Identification – Evaluate existing data and define biological endpoints.

- Plan Development – Draft an evidence-based testing / justification strategy.

- Regulatory Alignment – Adapt the plan for MDR, FDA, or other market submissions.

- Final Approval – Delivery of a clear, auditable BEP ready for execution or submission.

Partnering with Cormica for your BEP

- Regulatory Confidence of your submission: Fully compliant with ISO 10993-1:2025, MDR, and FDA expectations.

- Reduced Costs & Timelines: Intelligent data leveraging to avoid unnecessary testing.

- Depth of Expertise: Delivered by registered biologists, toxicologists and Clinical experts with cross-sector experience from implantable to respiratory systems.

- Integrated Approach: Each BEP connects risk management, chemistry, and clinical strategy into one cohesive regulatory pathway.

- Strategic Value: You gain not just compliance, but a biological safety narrative that strengthens your device’s scientific and commercial positioning.

Frequently Asked Questions about BEP's

Regulators now require a BEP as the foundation of any biocompatibility assessment under ISO 10993-1 and MDR. To be accepted, it must be authored and signed by a qualified or certified biocompatibility specialist with relevant regulatory and toxicological expertise. A Biological Evaluation Plan defines the scientific rationale for demonstrating device safety and ensures that only scientifically justified tests are performed.

Typically 5–15 working days, depending on device complexity and technical data availability. Complex or combination products may require slightly longer.

Yes, provided materials, processes, and sterilization methods are equivalent. Our experts perform detailed equivalence and gap analyses to justify the reuse of existing data, saving time and cost.

We typically require the device Bill of Materials (BOM), manufacturing and sterilisation process descriptions including additives, mould release and cleaning agents, material and supplier information, product drawings or photos, and a copy of the IFU (Instructions for Use). Any existing test reports or toxicological data are also highly valuable for reducing unnecessary testing and overall risk for the device.

The IFU supports definition of the intended clinical use, contact duration with healthcare professional and patient, highlights underlying, sometimes critical factors (temperature, additional sterilization- all contribute to thorough tailored determination biological endpoints under ISO 10993-1. Without it, biological risks may be misclassified, leading to incomplete or excessive testing.

Typically BEP is required for the Final Medical Device.

However, if the prototype will be used for design validation, clinical investigation, or pre-market submission, then Biological Evaluation is advised.

We can support your proof-of-concept or non-clinical prototype projects by consulting with simplified biological assessment and literature searches. Our specialists can advise on the most appropriate and efficient approach for your development stage.

Packaging materials can significantly affect extractables and leachables outcomes. Ideally, packaging details should be available before finalising the BEP to ensure a complete risk evaluation. However, if packaging is still under development, we can provisionally define the plan and update it once final materials are confirmed.

Absolutely. We provide independent, science-based recommendations on appropriate in-vitro, analytical, or animal testing methods depending on device type, contact category, and material chemistry. Our goal is to optimise your testing strategy to meet ISO 10993 and regulatory expectations with minimal redundancy.

A standard BEP typically requires 5–10 working days once all required information is received. More complex combination products or implantable devices may require longer, particularly if detailed material or chemical characterization data must be reviewed.

- BEP (Biological Evaluation Plan): Defines the overall strategy and rationale before testing.

- TRA (Toxicological Risk Assessment): Evaluates patient exposure to chemical substances and their toxicological significance (ISO 10993-17).

- BER (Biological Evaluation Report): Summarises all biological data, test results, and risk assessments after testing to conclude on biocompatibility.

A formal BEP may not be required for non-patient-contacting devices (e.g., external hardware or software components). However, regulators still expect a documented justification or biological risk statement within the technical file explaining why a full biological evaluation is not applicable.

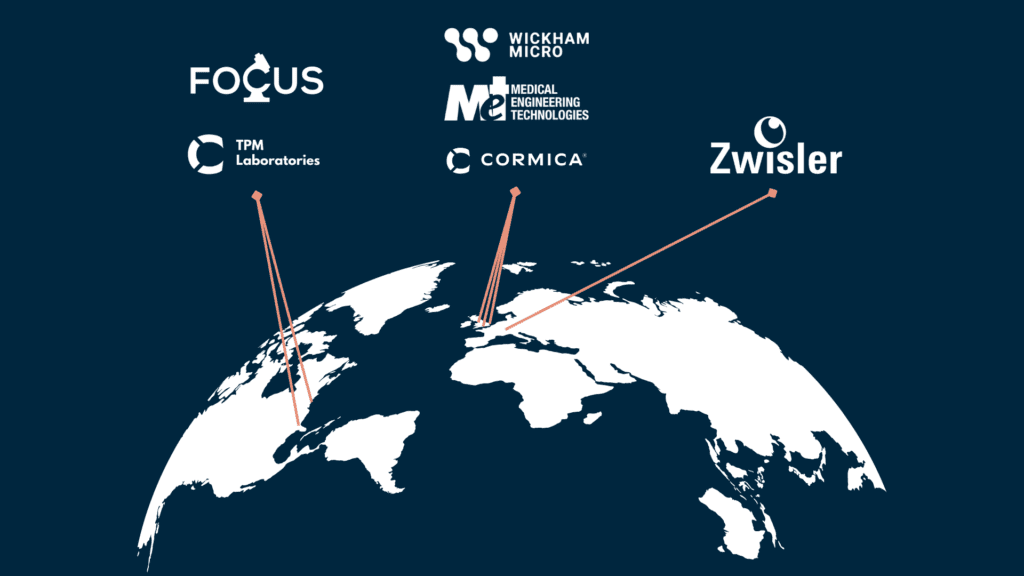

Laboratories near you, supporting global product success

With accredited laboratories in the UK, EU and US, we support pharmaceutical, medical device and combination product manufacturers worldwide. Local support combined with global quality, delivered by teams who understand your regulatory requirements.

Cormica's Support and Consultancy Services

Regulatory Consultancy

- ISO 10993 Biocompatibility Testing

- Biological Evaluation Plans (BEP)

- Biological Evaluation Reports (BER)

- Clinical Evaluation Plans (CEP) & Reports (CER)

- US FDA Submission Support

- UK & EU MDR Submission Support

- Toxicological Risk Analysis

- Biological Gap Analysis

- Post-Market Surveillance (including PSUR)

Development & Lifecycle Support

- Materials Selection & Collection

- Supply Chain Support

- Packaging Consultancy

- Design & Verification Support

- Late-Stage Development Issue Resolution

- Pack Market Remediation

Our Clients’ Experiences