X-ray Diffraction

A Simple Approach

Type:

Published:

Author:

Caroline German

Operations Director

Cormica Bradford Ltd

Request call back

X-ray diffraction (XRD) analysis provides critical information regarding the solid form of your product, supporting drug discovery and development, regulatory submissions, formulation development, batch release and storage stability. X-ray powder diffraction is rapid, non-destructive, adaptable and very widely applied.

Characterisation by X-ray diffraction is fundamental to determining key properties such as:

- Identification

- Solid form benchmarking

- Polymorphic form

- Crystallinity and amorphicity

- Active content assay

- Phase purity and phase quantification

- Stoichiometry

- Physical stability

XRD has a key role to play in many applications including:

- Lead Candidate Optimisation

- Physical Form Benchmarking

- GMP Batch Release Testing

- Manufacturing Investigations

- Contaminant / Foreign Body

- Identification Full ICH Storage Stability Testing

- Medical Device Testing

- Composition / Stoichiometry / Phase ID

- Salt & Polymorph Screens

- Crystallinity-Amorphicity Investigations

- Formulation & Processing

- Micronisation / Nanoparticles / Lyophilisation

- De-formulation & Reverse Engineering

Solid Form, Polymorphism and Phase Purity

Many solid materials, such as pharmaceutical intermediates, APIs and final products, can exhibit polymorphism – the ability of a solid to express more than one crystalline form – and different polymorphs of the same material can exhibit startlingly different properties, from melting point and hydration state, to dissolution performance, long term physical stability and bioavailability. Hence, understanding the polymorphic behaviour of your product is of key importance – and a regulatory expectation.

XRD can be used to understand this behaviour, as each polymorph – or pseudo-polymorph, solvate, co-crystal, or salt form – will demonstrate a unique diffraction pattern. This facilitates the monitoring of any polymorphic or solid form changes that may occur during development, scale up, manufacturing or on storage, and also enables optimization of solid form, by allowing for a close understanding of the form being expressed.

Moreover, XRD is the key technique utilized to carry out polymorphic risk assessments, polymorph and salt screening studies, phase purity assessments, and batch release testing for solid form.

Methodologies can be qualitative (pattern matching), function as limit tests or be fully quantitative.

Crystallinity and Amorphicity

XRD analysis enables the qualitative and quantitative assessment of the degree of crystallinity of samples. By utilizing the relationship between crystallinity and pattern intensity, and controlling for factors such as particle size and morphology, indicative comparisons may be made between samples of the same type.

Quantitative methodologies can require the preparation of calibration standards; our micronizing, milling and blending capability enable the preparation of amorphous reference materials and calibration blends.

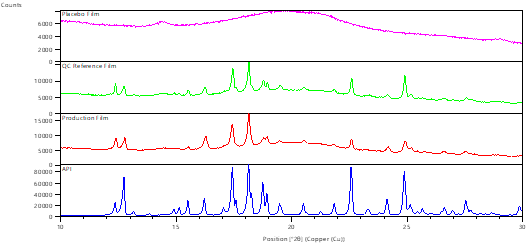

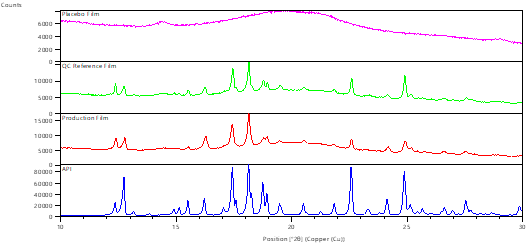

A Simple Approach

While it is very feasible, and indeed necessary, to develop bespoke XRD methods for many of the applications discussed above, in fact a great deal of information can be gathered about a sample using a relatively simple approach. This won’t provide, for instance, quantification data, but is very capable of answering questions about solid form identity and benchmarking, semi-quantitative crystallinity assessment, physical stability on storage, and sample-to-sample or sample-to-reference material comparisons.

For this approach samples are typically requested to be dry powders, suspensions or films, suitable for presenting to the X-ray diffractometer with minimal preparation and using standard sample holders. Sample mass / quantities required are dependent on bulk density (powders) and analyte loading (suspensions and films).

Subsequently, an in-house method in reflection or transmission geometry is used to generate simple diffraction patterns. If required, a reference sample provided by client can be tested using the same approach, for comparison of data with that obtained for the test sample(s).

- Range 3 – 40 °2theta or 3 – 80 °2theta

- Reflection or transmission geometry using standard instrument optics

- Standard step size and time per step

- Reflection-transmission sample spinner

- Single replicate analysis per sample

If wished, brief method optimisation can be completed ahead of testing.

- Optimisation of measurement parameters (e.g., step size and time per step) to achieve improved resolution and intensity.

Instrumentation

Cormica Bradford Limited carry out this testing using both their Bruker D8 Advance (reflection geometry) and Malvern Panalytical Empyrean S3 (reflection and transmission geometry) X-ray diffractometers. In addition to simple analysis, testing using a high throughput approach and environmental stage is available, plus quantitative method development and validation.

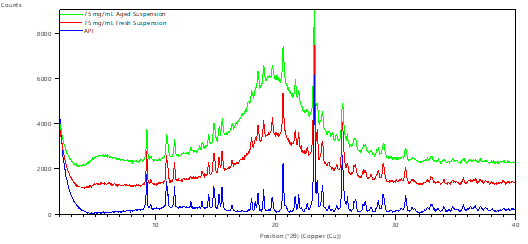

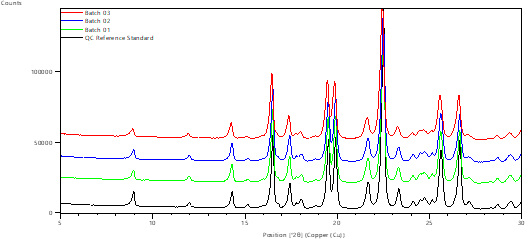

Examples of data obtained are shown below: